Steam & Gas turbine

The turbine sits at the heart of a power plant. As one of the most critical assets, it requires advanced control options and in-depth knowledge to maintain and extend its life cycle.

In the current power scenario, turbines are also required to offer an unprecedented level of flexibility to compensate for electrical grid fluctuations, affecting their performances and lifecycle.

Advanced diagnostics

From turbine automation and advanced diagnostics to predictive maintenance, our solutions enable safe, smart, and sustainable operations and maintenance, preserving equipment integrity and preventing/predicting potential disruptions.

Tailored solutions

Specific to gas, steam – both utility and industrial – and hydro turbines, our tailored control & diagnostic solutions are complemented by a wide and fully integrated portfolio of excitation and synchronization equipment, electrical systems, and digital packages.

Steam turbine control

Steam turbine control solutions for utility and industrial applications include governor control, turbine and generator protection, automatic startup, rotor stress evaluation, auxiliary control, valve management, condition monitoring, auto-synchronization, excitation, frequency control, extraction control, bypass control, unit control, etc.

All control and protection functions (DCS and mechanical) are included to ensure safe, reliable, and economical operations.

Gas turbine control

Starting at the heart of a combined cycle power plant or a simple cycle power plant, we can integrate your gas turbine control system into a complete plant control solution.

Our gas turbine control solutions include fuel control, startup sequence, speed-load-temperature closed loop control, overspeed protection, anti-surge protection, generator protection, auxiliary control, condition monitoring, auto-synchronization, excitation, frequency control, etc.

Our gas turbine application experience includes peaking units, combined cycle units, remote start units, and black start units.

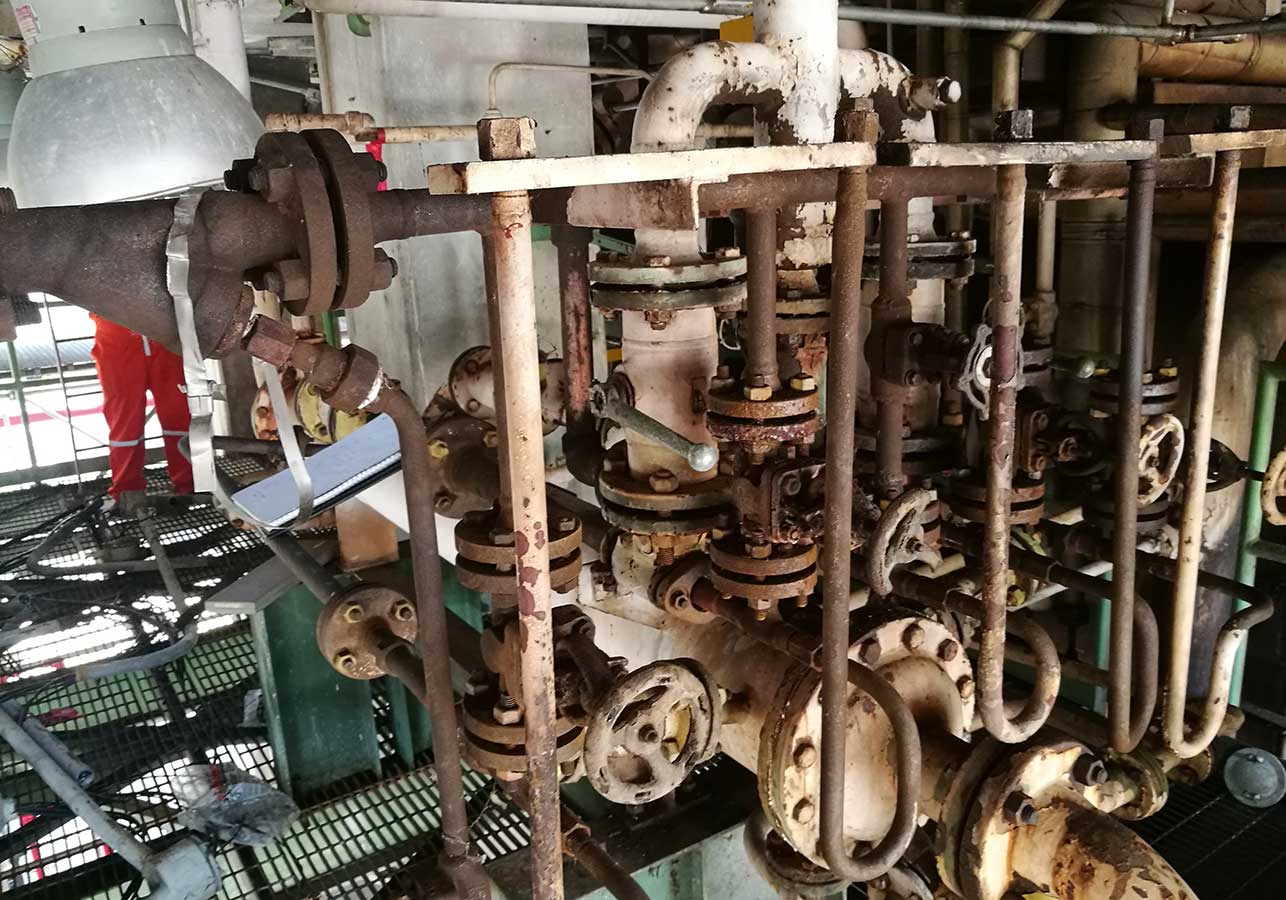

Fuel Skid

We design and manufacture Fuel Gas and Fuel Oil Skid Systems, including both mechanical and electro-instrumental components. We provide turnkey solutions and supply all necessary instrumentation, mechanical designs, and interconnections. Our designs excel in availability, maintainability, operability, and run length.

Our Fuel Gas Skids are designed to cover the required rangeability defined by the gas turbine, boiler, or fired heater. They can also be integrated with a pressure reduction Skid, KO drum filtration, and heating system using electric, steam, or gas heaters.

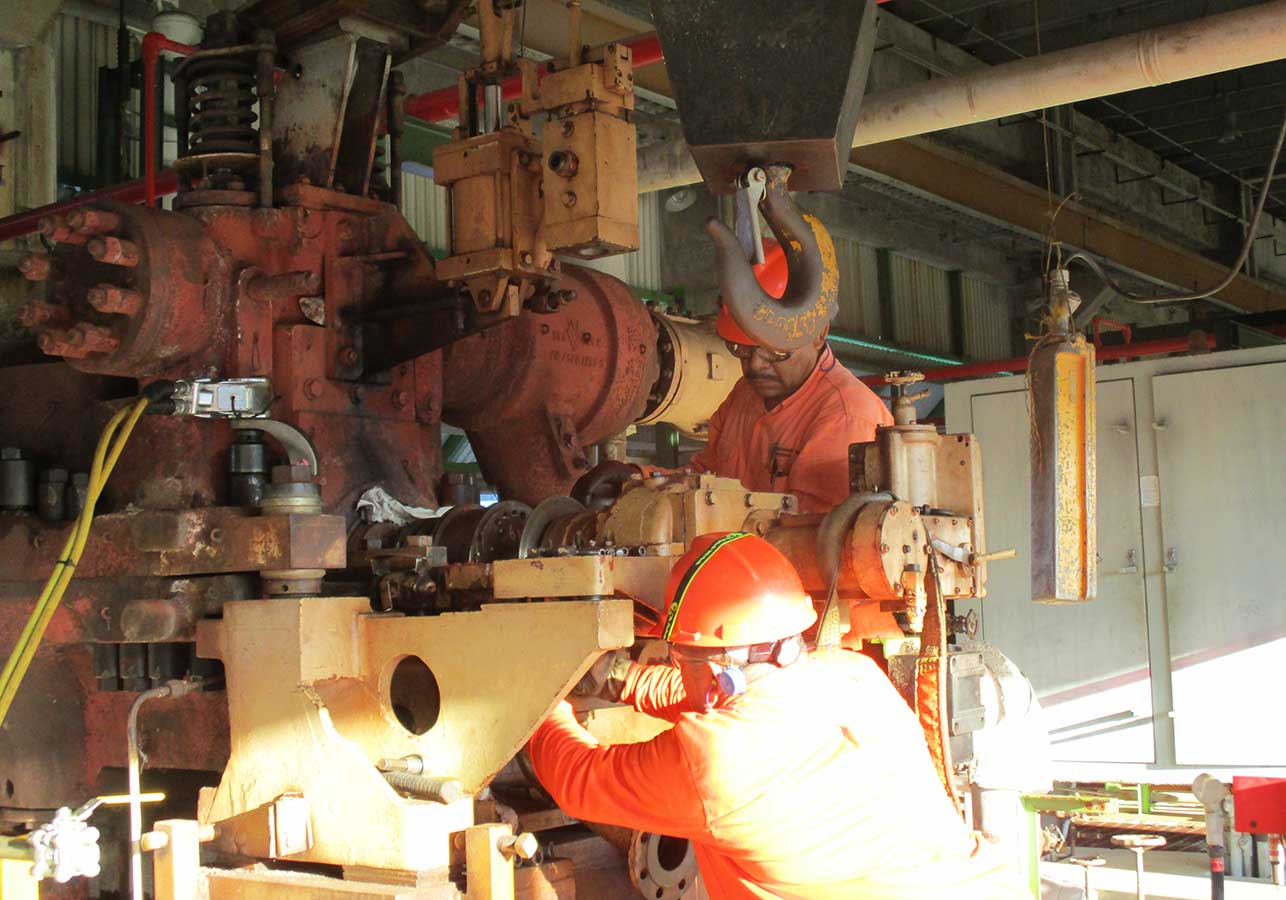

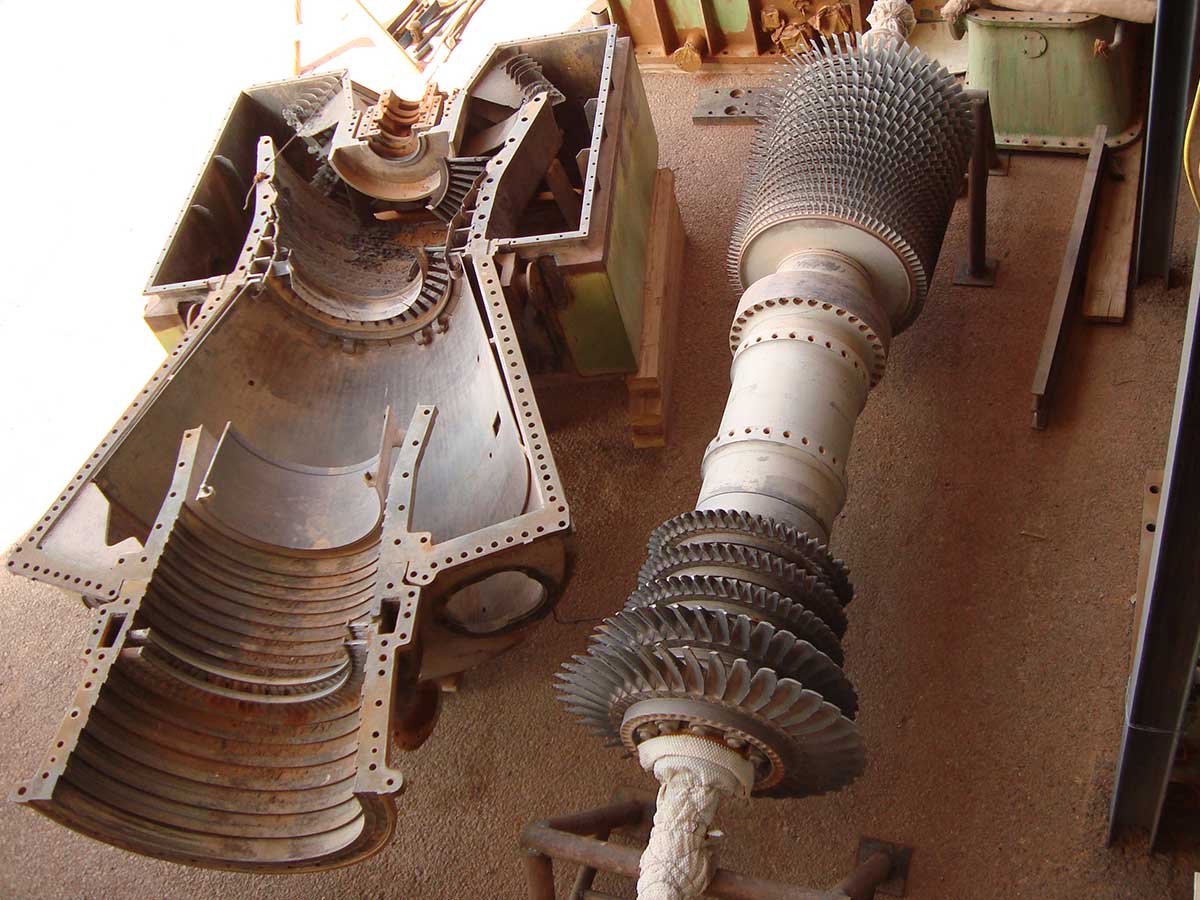

Revamping

Our portfolio offers several options to increase the availability and reliability of gas & steam turbines and auxiliary equipment. We offer customized conversions based on customer requests or specific site surveys for equipment to meet changing needs.

Through our engineering department, we provide new, economical, and more sustainable solutions to renew and revamp your units. We design, rethink, and implement new elements that our customers need to maximize their installation’s efficiency.

Before & After